Malaysia’s semiconductor industry is set to benefit from the ongoing US-China tech war as companies seek alternatives in the global chip supply chain. With the US increasing trade restrictions on China, experts say more businesses are turning to Malaysia as a neutral and viable option.

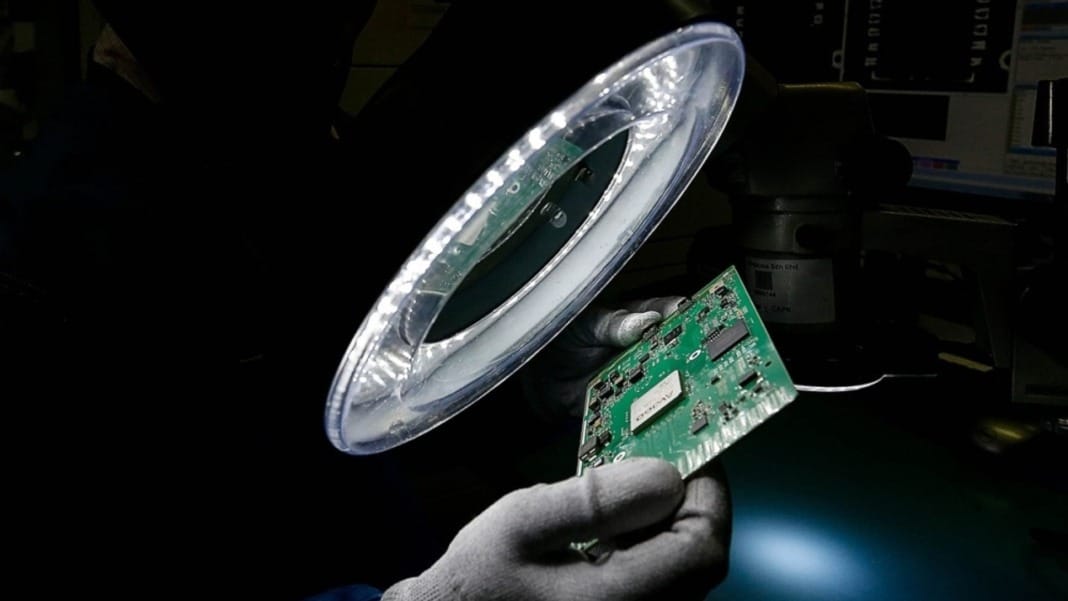

At the China Conference: Southeast Asia 2025, held in Kuala Lumpur on Monday, industry leaders highlighted how Malaysia’s semiconductor sector is seeing new opportunities. The country is particularly strong in back-end operations such as chip testing and packaging, making it an attractive choice.

“For the semiconductor industry, the impact on China will benefit Malaysia,” said Wong Siew-hai, president of the Malaysia Semiconductor Industry Association (MSIA). He explained that Malaysia’s neutrality allows companies to serve the US and China without being caught in geopolitical tensions.

Government support boosts Malaysia’s semiconductor growth

Malaysia has been actively strengthening its position in the semiconductor industry. In May last year, the government launched the National Semiconductor Strategy, backed by RM25 billion (US$5.6 billion) in funding and incentives. The plan aims to transform Malaysia into a major semiconductor hub by expanding into chip design, high-end manufacturing, and advanced packaging over the next decade.

Lim Li Lian, deputy director at the Malaysian think tank Research For Social Advancement, echoed Wong’s sentiments. “Malaysia’s neutral brand is strong,” she said. “One of Malaysia’s best strategies is its semiconductor technologies, services, and companies.”

Malaysia has been developing its semiconductor sector since the 1970s and is now the sixth-largest semiconductor exporter worldwide. According to MSIA data, the country accounts for 13% of the global semiconductor testing and packaging market share.

Foreign direct investment (FDI) in Malaysia has surged due to US restrictions on China. Lim noted that more international companies are eyeing Malaysia as a cost-effective manufacturing base. However, she cautioned that this trend might not last, given US efforts to bring more manufacturing back to its borders.

“Malaysia needs to diversify its export markets,” Lim said. “The FDI boost from companies using Malaysia to export to the US may be short-lived, so we must explore other opportunities.”

Challenges ahead in semiconductor expansion

Despite its growth, Malaysia still faces challenges in further advancing the semiconductor supply chain. Industry experts pointed out that while Malaysia is strong in back-end processes, it lags in front-end areas such as integrated circuit design and wafer fabrication.

Phang Ah-tong, independent non-executive chairman at JF Technology, a Malaysian test engineering firm, noted that Malaysia needs to focus on developing these high-value segments. He highlighted the importance of strengthening the country’s role in graphics processing units (GPUs), which are crucial for artificial intelligence and data centres.

MSIA’s Wong also stressed the need for more home-grown semiconductor companies. “In the design sector, we have about 30 companies, but only five or six are Malaysian,” he said. “That is not enough.”

As Malaysia positions itself as a key player in the semiconductor industry, its neutrality and strong government support provide an advantage. However, experts agree that long-term success will depend on diversifying export markets and investing in advanced semiconductor technologies.